SAP MRP Run Automation

Ensure error-free and smooth operation of your material requirements planning in SAP. Easily plan the MRP run with HONICO Workload Automation.

Automation of Material Requirements Planning (MRP run) in SAP

The supply of materials in line with demand is a crucial success factor for companies. Errors and delays in the supply chain can cause immense costs. The calculation of current inventories is indispensable to ensure correct procurement in purchasing and production.

Workload Automation from HONICO can guarantee you a smooth SAP MRP run. Our solution enables centralized and modern job scheduling: Cross-platform hyrid and in the cloud. So avoid high error costs and optimize the MRP run by keeping ‘just in time’.

What is the SAP MRP run?

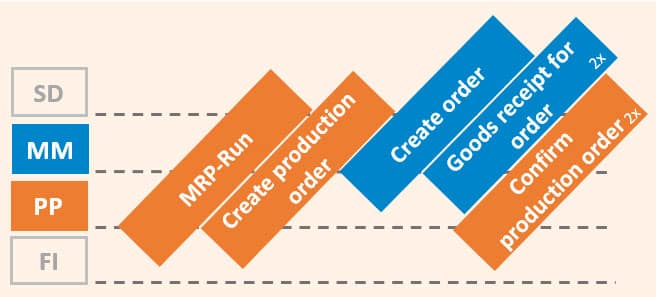

SAP MRP stands for Material Requirements Planning and is a standard SAP process. The MRP run ensures the availability of materials for production and purchasing in the company by determining the requirements. Based on this automatic query, subsequent processes such as planned orders and purchase requisitions are then created to ensure timely procurement and avoid delivery bottlenecks.

Why automate SAP MRP run?

The MRP run in SAP is already automated in many cases, but the possibilities are limited. To take advantage of low-load times, the MRP is usually scheduled in the background and during nighttime processing. Automation in SAP is scheduled on a time-controlled basis. In case of an error, the base administrator may see it too late or not at all. If the MRP run stops, it has to be restarted manually. This means a loss of time and, if the procurement is not secured, a loss of money for the company, which can be avoided.

Workload Automation closes precisely this gap: scheduling at low-load times and time buffers are no longer necessary and the MRP is automatically restarted in the event of an error. If the run does stop, an error behavior can be preconfigured and / or an employee can be notified with alerting. The monitoring of HONICO’s modern solution also provides an up-to-date overview of the status of running and planned background jobs at all times.

The market leader for air conditioning systems was looking for a replacement for its job scheduling at the time. Learn how Stiebel Eltron was able to create more transparency and control for job chains such as the MRP run and invoicing by migrating to HONICO BatchMan

Advantage of automated MRP run

- the complete process is fully integrated in SAP

- Graphical representation & clear monitoring

- Reduction of manual processes to one third

- Automatic error handling and load distribution

- Low code approach for fast interface integration